At present, you may seek for Kevlar fabric roll to build armor, protect your high-tech battery pack, or want to build some particular components. We are here with the most experienced engineer and weaving machines that can optimize your success and save you time to find a reliable manufacturing supplier. Please feel free to request 1 sq. meter for a test, we can make the delivery ASAP. If you’ve achieved the Minimum Order Quantity (MOQ) of make-to-order, we could produce a sample for you after receiving the specifications and CAD files, even including the cutting and sewing works. This means you can get an out-of-the-box component.

As world-known ultra-high strength, high modulus, and high-temperature resistant fiber, Kevlar®, with the filaments Denier of 200D, 400D, 1000D, 1500D, and 3000D, and the type of Kevlar 29, Kevlar 49, Twaron 1000, Twaron 2000/2040, we managed to weave the fabric in the thickness from 0.09mm to 0.58mm, and from 50sqm to 420gsm in nominal/areal weight. Beyond the range, we won’t stock in the warehouse but can develop specifically as you requested, and the MOQ is acceptable for most clients.

Woven Fabric Made of Kevlar® | Para-aramid

100/200/240/420gsm models are in-stock

You could buy 1 yard/meter for a test, then have a full roll of 100 meters as formal procurement.

| Type | Weave | Weight(gsm) | Filaments | Thickness(mm) | Status |

|---|---|---|---|---|---|

| AF60P | plain | 60 | 200DEN | 0.1 | In-stock |

| AF100P | plain | 100 | 400DEN | 0.17 | In-stock |

| AF120 | plain/twill | 120 | 400DEN | 0.19 | Make-to-Orde |

| AF200P | plain | 200 | 1000DEN | 0.26 | In-stock |

| AF230BT | twill | 230 | 1500DEN | 0.3 | In-stock |

| AF240BP | plain | 240 | 1500DEN | 0.3 | Make-to-Orde |

| AF240P | plain | 240 | 1500DEN | 0.29 | In-stock |

| AF300 | plain/twill | 300 | 1500DEN | 0.42 | Make-to-Orde |

| AF420T | twill | 420 | 3000DEN | 0.58 | In-stock |

Please be aware of:

- Generally, the Kevlar fabrics are the same width of 1 meter (39″), maximum make-to-order width is 1.5 meter (59″).

- An entire roll of Kevlar fabric contains 100 meters (109 yards) in length.

- The A4-size free samples are available to send, otherwise, you could buy 1 square meter to test if needed.

- Not all models are listed as above, if there is any unlisted model you demanded, please feel free to inquire.

- Most of the models are in golden color, and only AF230BT & AF240BP are in black. Other colors are available made-to-order, like red, black-red(twill), black-golden(twill), etc.

- The listed models are basically made of Kevlar 29 or Twaron Type 1000. If you demand the high-modulus-weight fabric made of Kevlar 49/Twaron Type 2000/2040, please inquire at kevin@sanmau.net immediately, this is the only way to get the military-level fabric.

Kevlar Fabric on Roll

Kevlar Fabric in Carton Boxes

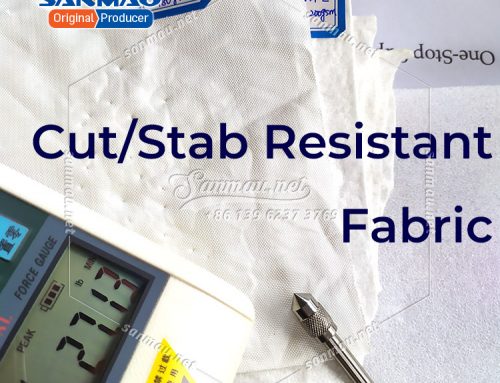

Apart from the WOVEN FABRIC, there are three kinds of fabrics made of Kevlar material, but have different production techniques:

- Uni-directional Fabric: more like a plastic sheet than soft textile, but it’s a cost-efficient bulletproof material for stopping handgun bullets.

- Knitted Fabric: mostly used to make cut-proof and heat-resistant gloves, and protective suits, applied as lining fabric.

- Non-woven Fabric: it’s a kind of thin or thick felt according to its areal weight produced, in good abrasion and filter features, can bear heat up to 250~300 degrees Celsius, and serve for a long time.

Kevler Fabric Rolls in Stock

There are several most used models of woven fabrics which were made of Kevlar or Twaron filaments. Please feel free to send me an email, I’ll be glad to have your inquiry and reply with all the infomation you demand.

Q&A of Kevlar Fabrics

Could I buy a small quantity for a test?

Sure, you can buy 1 sq. meter to test before any formal purchase, and we recommended this way to avoid selling/buying the improper fabric. They are not ordinary materials and not cheap though. After a satisfactory examination or prototype building, you will have the confidence to purchase Kevlar fabric rolls properly.

How many layers of Kevlar fabric can stop bullets?

For different kinds of guns and bullets, the layers will be different. In general, 36~48 layers of 200gsm Kevlar woven/UD fabrics would stop the 7.62mm bullets. As a matter of fact, stopping is not enough for good protection, combining with a solid plate and a sponge is the minimum safe request for the man-wear bulletproof vests, and combined ceramic/SiC/Ai2O3 plats with layers of Kevlar fabrics will be the best bulletproof equipment, which is exactly the solution with most of the military.

Should I choose the woven fabric or UD fabric to build a reliable bulletproof vest?

Kevlar UD fabric is the better cost-efficient material to make pistol-bullet-proof vests and suits. Please refer to the UD fabric page: Bulletproof Uni-directional Fabric

| Features→ Material↓ |

Tensile Strength | Elongation at Break | Abrasion Resistance | Ultraviolet (UV) Resistance | Flame Resistance | Chemical Resistance (Acid) | Chemical Resistance (Alkali) | Chemical Resistance (Organic Solvent) |

| Kevlar(Para-aramid) | Excellent | Low | Excellent | Poor | Exceptional | Excellent | Good | Excellent |

| Dyneema(UHMWPE) | Excellent | Low | Excellent | Exceptional | Poor | Excellent | Good | Excellent |

| Carbon Fiber | Excellent | Low | Excellent | Good | Excellent | Excellent | Excellent | Excellent |

| Nylon Fiber | Ordinary | Medium | Excellent | Ordinary | Poor | Ordinary | Good | Ordinary |

| Polyester Fiber | Ordinary | Medium | Good | Poor | Poor | Excellent | Good | Excellent |

| Polypropylene Fiber | Ordinary | Medium | Ordinary | Poor | Poor | Good | Good | Good |

Applications of Kevlar® | Para-aramid Fabric

Define: Kevlar® & Nomex® Fiber

These two brands belong to DuPontTM. They are the most used ARAMID material, Kevlar® is para-aramid and always has a natural color of yellow, on the other hand, Nomex® is meta-aramid and has a natural color of white.

Kevlar® has successfully emerged as one of the ultra high-performance fibers since it’s been first introduced by Stephanie Kwolek in 1971 and was registered by DuPont as a famous para-aramid material commercial brand. This magic fiber has various amazing features: long-term working in high-temperature environments, high tensile load, and low elongation.

Advanced Properties of Kevlar® | Para-Aramid fiber

High strength-to-weight ratio

Low elongation to break

Low thermal shrinkage

Good heat & flame resistance

Self-extinguishing flame retardant properties

Good chemical resistance

Excellent bulletproof/ballistic properties

High cut resistance (not so easy to cut off than normal fibers)

UV resistance is available (ONLY in dope-dyed black and other non-original yellow color fiber)

UV resistance is poor (the original yellow fiber, and please notice this is the MAIN WEAKNESS for all Kevlar analog fibers)

Common Types & Deniers

T-29: Standard Modulus

T-49: High Modulus

AP: 15% higher tenacity than T-29

KM2: Optimized ballistic resistance

Deniers: 200, 380, 400, 750, 800, 1000, 1420, 2160, 2250, 2840, 3000, 7100

Advanced Properties of Nomex® | Meta-Aramid fiber

Lower elongation to break

the 4th level of dye colorfastness, dyeable

Low thermal shrinkage

Excellent heat & flame resistance

Self-extinguishing flame retardant properties

Soft-hand yields good textile properties

High chemical resistance

Common Types & Deniers

T-430: Filament Yarn

Deniers: 200, 1200, 1600, 2400

Terms of Cooperation

For more details, PLEASE DO NOT HESITATE to write me an e-mail, or just dial the number directly.

|

|||||||||||||||