Most Used Polyimide Fabric

About Polyimide

Polyimides (PIs) are high-temperature engineering polymers originally developed by the DuPont™ Company. Polyimides exhibit an exceptional combination of thermal stability (>500 °C), mechanical toughness, and chemical resistance. They have excellent dielectric properties and an inherently low coefficient of thermal expansion.

In general way, the most common products of polyimide are tapes which were usually named as Kapton® Film. On recent years the polyimide fiber and its products have been applied as the better fireproof material to replace para-aramid/Kevlar®, for it can bear much higher temperature.

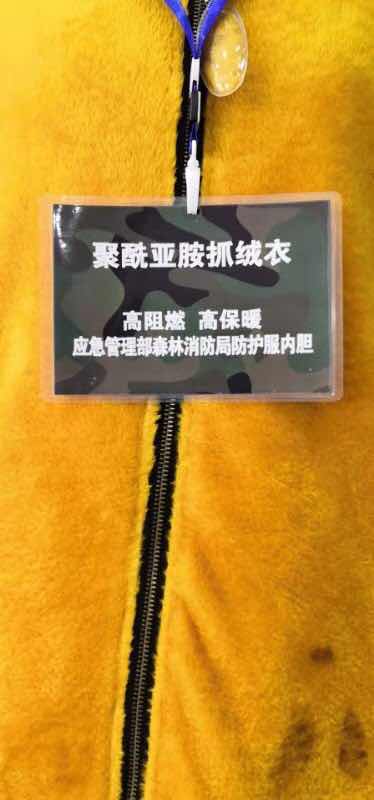

Knitted Fleece Polyimide Fabric

Natural Golden Color, in thewidth of 150cm, weight of 260g/m2. It’s might be the best warm-keeping material of fight jacket, polar minitary uniform which required ULTRA FLAM RESISANT feature.

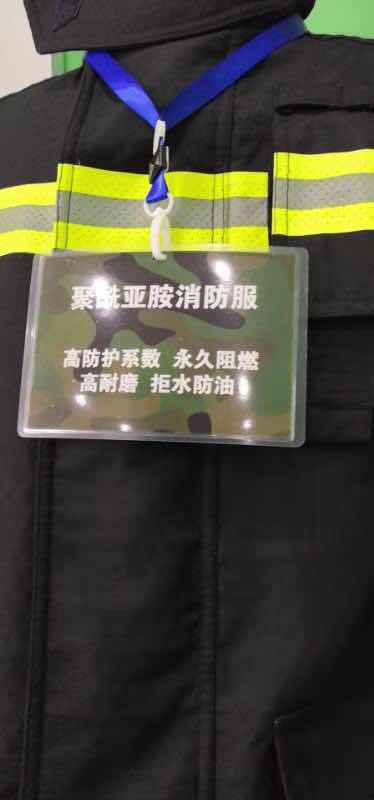

Woven Polyimide Fabric

Dark Green, in the fabric width of 180cm, weight of 440g/m2

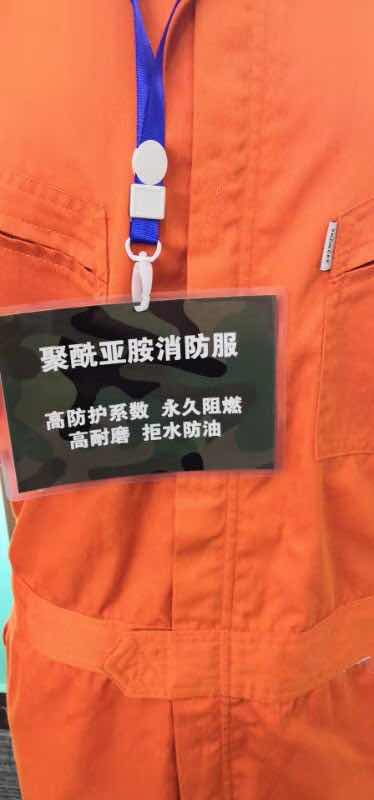

Woven Polyimide Fabric

Orange, in the fabric width of 160cm, weight of 230g/m2

Woven Polyimide Fabric

Yellow, in the fabric width of 150cm, weight of 200g/m2

Details of Polyimide Fabric

Applications of Polyimide Fabric

Terms of Cooperation

For more details, PLEASE DO NOT HESITATE to write me an e-mail, or just dial the number directly.

|

|||||||||||||||