Advantages of Meta-aramid (Nomex) Webbing

- flame resistant, as soos as get away from fire, the burn and carbonization will stop immediately;

- inherent fire retardant, easy to weave to every patterns;

- eco-friendly, do no need any chemical treatment to obtain the feature

- meet NFPA 1971 standard;

- meet FAR25.853 standard.

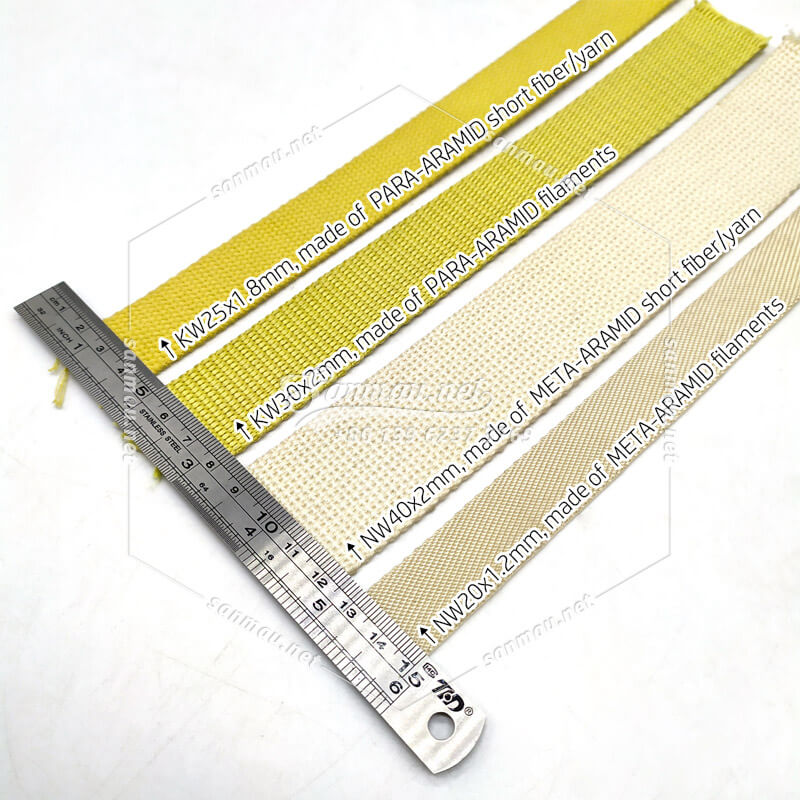

How to distinguish Kevlar from Nomex as webbing?

Para-aramid(Kevlar) is hard to dye, its original color is gold(yellow), and have several DOPE-DYEING (mixed color masterbatch with raw liquid before the filaments were extruded) colors: red, blue, green and black, etc. So the most common Kevlar webbing appears as its raw color. However, we can offer the non-yellow webbing which can be made of existing dope-dyeing filaments.

Meta-aramid(Nomex) can be dyed to any color, just like polyester or nylon(of course cost a little more). However, the filaments of meta-aramid are rarely used because of its price, so the meta-aramid webbing we developed generally are made of short-fibers/yarn. Please note that meta-aramid have much better performance in fire-resistant features, not matter compared with chemical-treated fireproof polyester fibers, or modacrylic fibers.

Terms of Cooperation

For more details, PLEASE DO NOT HESITATE to write me an e-mail, or just dial the number directly.

|

|||||||||||||||