About ESD & Anti-static

Static electricity is a by-product of the manufacturing industry. Whirring belts, rotating wheels, plastics and synthetics running through machines at high speed, all create sources of static which in turn, can seriously impair product quality, increase reject rates and reduce profitability.

Sanmau now has gathered three types of conductive fiber to make useful anti-static rope. One is a combination of micro-steel fiber and host fiber, but not pure steel wire, the others are silver and copper fibers. These conductive fibers have the advantage of tenacity and flexibility of normal fiber and the conductivity of the metal. It also has reliable physical and chemical features and can serve in the long term.

The features of our ESD conductive anti-static thread | rope| straps:

-

Excellent conductivity, much lower than 10^3OHM

-

In the same quality level, half the price compared with others

-

Long-term lifetime, which means fewer parts replacement and expenses.

-

Can be customized with various material as coring rope

- Various materials for choice: silver, copper, stainless steel. All the materials appear as fibers/filaments which can be twisted to threads, braided to ropes, and woven to straps/webbings.

For rope and straps, the material of the core in alternatives of Polyester, Nylon, PP, UHMWPE, Kevlar/para-aramid, Nomex/meta-aramid, etc.

Color: appeared as the conductive fiber’s color, inside with the natural color of the fiber as a core.

The conductive threads have the diameters from 0.1mm to 0.5mm.

The diameters of ropes can be customized from 0.3mm to 20mm.

The conductive straps/webbing can be customized to 0.1~5mm in thickness, and 5~310mm in width.

All conductive materials can be used as an excellent Electrostatic Discharge(ESD) | antistatic product.

Please inform the details of usage or accurate specifications to ask for a free sample.

The Advantage of Our Customized Anti-static Rope

A better and effective way to discharge unwanted static electricity

- Versatile in use with rapid installation. In most applications, it can simply be draped over the material.

- Elastic anti-static rope usually used in the printing industry, with powerful magnetic O-ring to settle quickly.

- For many applications, our customized anti-static rope can meet your demand perfectly.

- Reduces high static charges by excellent conductivity, usually, we managed to have the resistance within 20.

- With at least three types of conductive fiber to make various final products.

- Raise the breaking force limit as high as you want, with Dyneema or Kevlar materials.

- Even were available for a winch, with a long-term lifetime of excellent abrasion resistance, like UHMWPE/Dyneema.

- It can be mixed with all the material we usually used, para-aramid, UHMWPE, aramid III, PBO, etc. Whatever the extreme performance you demand, we always can satisfy you.

- Lowest MOQ, a startup with 100 meters, no mention we are experienced in dealing with almost all kinds of hi-tech performance fiber.

- The outside diameter of the rope can be customized from 0.5mm to 20mm.

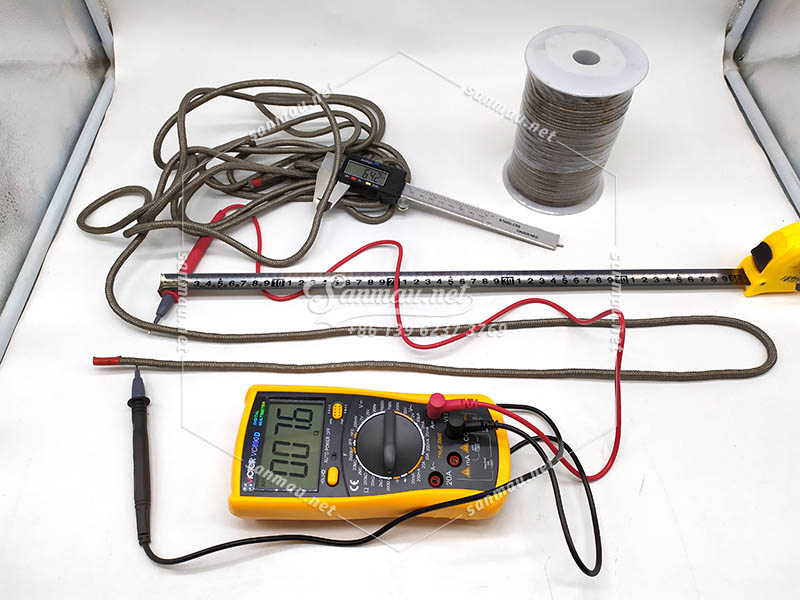

Antistatic UHMWPE Rope in 3.3mm OD

Special Made for Petroleum Industry, Winch workable.

Resistance/Conductivity: 8Ω/meter, Breaking Force: 650kgf

Applications of ESD Antistatic Thread | Rope | Straps

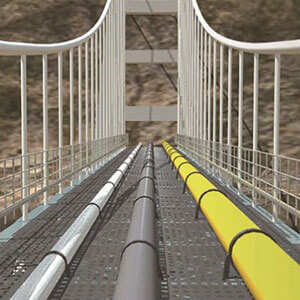

Petroleum Pipeline

Precision Electronic Elements Production

High Definition Printing

Antistatic Workbench

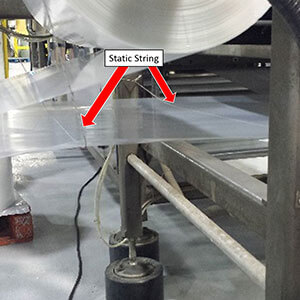

Film Electrostatic Discharge

Antistatic Curtains of Conductive Ropes

Frequently Used Antistatic Rope

Made of 316L stainless steel thread as the external layer,

in the diameter of 6mm, electrical resistance <10Ω/meter,

internal core can be customized as various materials: UHMWPE, aramid, Polyester, PP, etc.

Terms of Cooperation

Brand Name: SANMAU

Place of Origin: Dongguan, Guangdong, China (Mainland)

Materials for Choice: UHMWPE | Dyneema® | Spectra® Fibers, Para-aramid | Kevlar® Fibers, Meta-aramid | Nomex® Fibers, Polyimide Fibers, PBO Fibers, Silver|Copper|Steel Conductive Fibers, etc.

Technics: Twisting | Braiding | Weaving | Knitting | Resin Coating | PVC/PP/PE Extrusion Coating for Cords | Cutting & Sewing, etc.

Additional Features: Reflective strips added, Luminous strips added, reinforce the side of webbing by inner steel wire added, tensile strength reinforced, fireproof enhanced, etc.

Colors: Fibers’ Natural Color, Several Colored Fibers, Composite Patterns with Different Fibers.

The diameter of the Rope: 0.1 mm ~ 30 mm as you requested.

The diameter of the fiber cord(PE/PU jacket): 1 mm ~ 10 mm as you requested.

The width of the Webbing: 5 mm ~ 310 mm as you requested.

The thickness of the Webbing: 0.1 ~ 5 mm as you requested.

Nominal Weight of Fabric: 50 gsm ~ 500 gsm as you requested.

Manufacturing Capacity: 100,000 meters for the rope, 50,000 meters for the webbing, and 5,000 m2 for the fabric, monthly.

Production Mode: Made-To-Order, rare in-stock types. Please inquire about the details.

MOQ: goods’ value of greater than 1,000 USD per order.

Free Sample of Stock Goods: Available, freight charges only.

Sample Developing: Yes.

Payment: T/T for formal orders, Wise for sampling.

Packaging: Plastic bags, carton boxes, on pallets.

Shipment: by Sea LCL/FCL, or by Air Express via DHL/TNT/FedEx/UPS, etc.

Lead Time:

1~5 days for rope, 3~15 days for webbing, 3~7 days for fiber cord, 2 weeks for dyed-color webbing, 3 weeks for UD fabric and non-woven fabric trial production, 4 weeks plus for customized fabric weaving, follow-up finishing, and laminate, start from the payment were received.

Guarantee:

The specification sheet shall be attached to the ex-factory goods. We provide no less than a 1-year product performance guarantee through proper transport and storage conditions.

For more details, PLEASE DO NOT HESITATE to write me an e-mail, or just dial the number directly.

|

|||||||||||||||